Choosing the correct macro synthetic fiber is essential for achieving durable, crack-resistant, and structurally reliable concrete. With the growing replacement of traditional steel mesh and rebar in many applications, understanding how to evaluate fiber performance has become a key step for engineers, contractors, and project owners. This guide explains the core selection principles, performance indicators, and practical job-site considerations to help you choose the most suitable macro synthetic fiber for your project.

Before selecting any fiber type, clearly determine why fibers are being added to the concrete mix.

Macro fibers help reduce early-age cracking while concrete is still in the plastic stage. Although most macro synthetic fibers provide this benefit, it is typically considered a secondary function rather than the main design objective.

The primary role of macro synthetic fibers is to provide residual strength after cracking, improving toughness and load-carrying capacity. This allows fibers to replace or supplement steel reinforcement in many scenarios, including:

Slab-on-ground applications such as industrial floors, warehouses, and pavements

Structural elements like beams, columns, seismic components, and precast panels

Shotcrete systems for tunnel linings, slope stabilization, and swimming pools

Clearly defining the performance goal ensures the selected fiber meets engineering and code requirements.

Not all fibers perform the same. Evaluating the following technical characteristics is essential.

Different polymers provide different performance levels:

Polypropylene (PP): The most widely used material. Chemically inert and highly resistant to corrosion.

Polyolefin blends: Engineered hybrids designed for enhanced bonding and mechanical performance.

Polyvinyl Alcohol (PVA): Offers excellent bond strength and high modulus, but at a higher cost and with greater sensitivity to mix design.

Other materials: Nylon or polyester fibers may be used for specialized performance needs.

Look for fibers with at least 500 MPa to ensure they can handle loads post-cracking. This strength translates to reliable load-bearing capacity when it matters most.

Higher-modulus fibers (e.g., PVA) stiffen the concrete effectively, controlling crack widths under service loads for enhanced durability. Lower-modulus options (some PP variants) offer more ductility, ideal for applications needing flexibility.

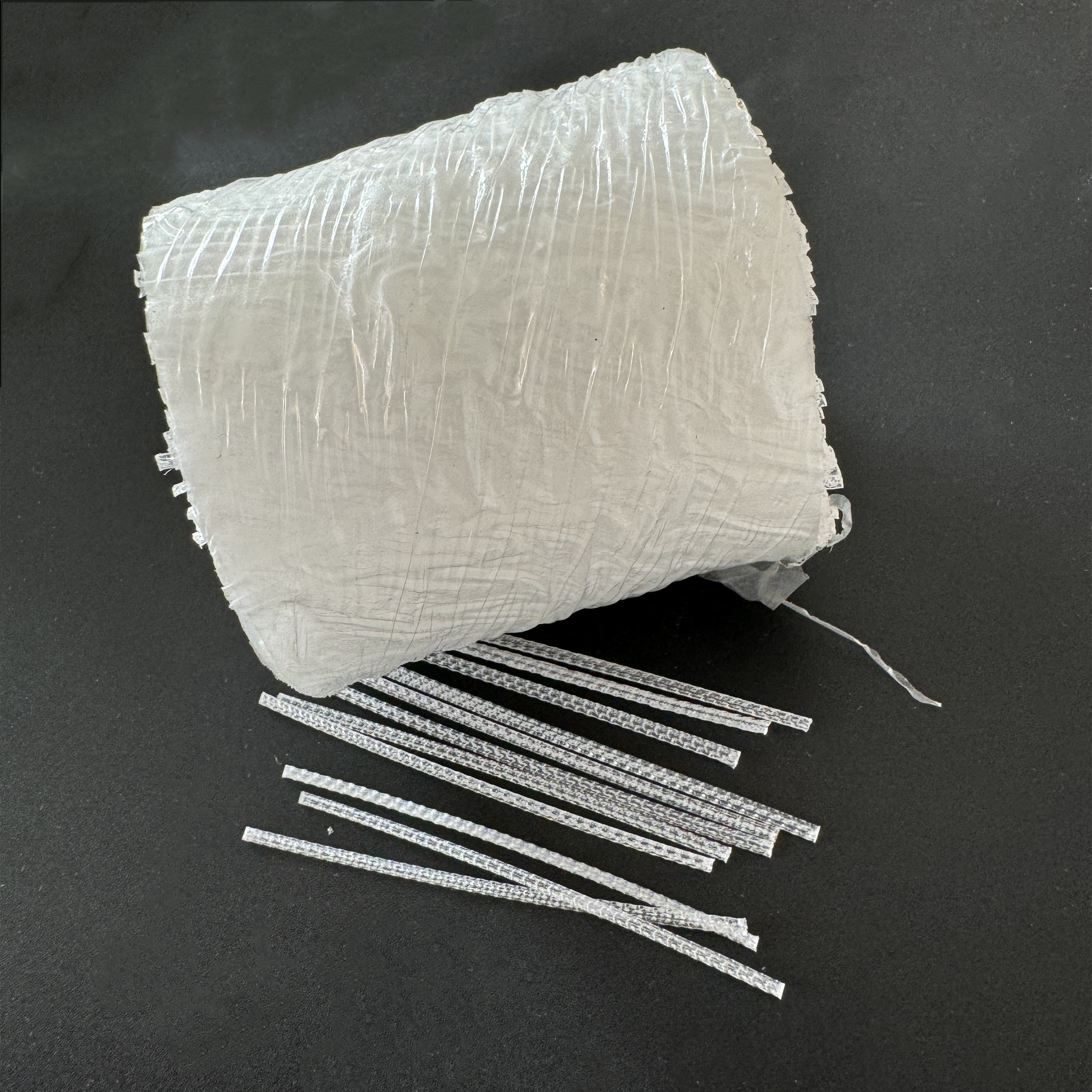

Effective bonding prevents fiber pull-out, which is critical for toughness. Opt for fibers with advanced surface treatments—textured, embossed, crimped, or fibrillated designs—or hooked/bundled ends. Stronger bonds mean higher energy absorption and better overall performance.

Typically measured in kg/m³ or lbs/yd³, dosages vary by purpose. For basic crack control, 1-3 kg/m³ suffices. Structural replacements demand higher rates (3-9 kg/m³). Confirm your batching plant's capability to dose accurately to avoid inconsistencies.

Evaluating these properties ensures the fiber integrates seamlessly with your concrete, maximizing its reinforcing potential.

Once you've assessed properties, tailor your choice to the specific application and regulatory requirements. This step bridges theory with practice, ensuring compliance and optimal results.

Slab-on-Ground Applications: Prioritize toughness specs to handle heavy loads and traffic. Fibers here reduce joint spacing and minimize curling, leading to smoother, longer-lasting surfaces.

Shotcrete Projects: Adhere to standards like ASTM C1550, which uses round determinant panel (RDP) testing to measure energy absorption in Joules. Specifiers often mandate minimum values, such as 40 Joules at 40mm deflection. Select fibers backed by verified test data to meet these benchmarks reliably.

Structural Elements: Follow codes like ACI 318, requiring minimum residual strength via tests such as ASTM C1609 (beam test). Engineers will define performance classes, so choose fibers that demonstrate proven results in these evaluations.

By matching fibers to these criteria, you not only comply with industry standards but also enhance safety and efficiency on-site.

Theory is great, but practicalities can make or break a project. Consider how the fiber will perform during mixing, placement, and finishing.

Mix Compatibility and Workability: Fibers may impact slump, especially at higher dosages or with longer lengths. Adjust your mix with water reducers or additional fines as needed. Consult your fiber supplier for tailored mix design advice to maintain pumpability and placement ease.

Pumping and Finishing: Shorter fibers (under 40mm) and moderate dosages pump smoothly. For intensive uses, select fibers resistant to balling or clustering. "Finish-friendly" options minimize surface issues, ensuring a professional look without extra effort.

Uniform Dispersion: Quality fibers feature anti-ballasting tech for even distribution, preventing weak spots in the concrete.

Corrosion Resistance: Unlike steel, macro synthetics are immune to chlorides, chemicals, and de-icing salts. This makes them ideal for marine structures, wastewater facilities, or cold-climate roads, extending service life and reducing maintenance costs.

Addressing these factors upfront streamlines operations, cuts downtime, and delivers a superior end product.

Choosing the right macro synthetic fiber is not simply about polymer type—it requires a performance-driven evaluation that considers:

Structural purpose

Mechanical properties

Compliance with testing standards

Real-world construction conditions

By aligning fiber characteristics with engineering requirements and job-site realities, project teams can achieve long-lasting durability, improved crack control, and cost-effective reinforcement—often without traditional steel.