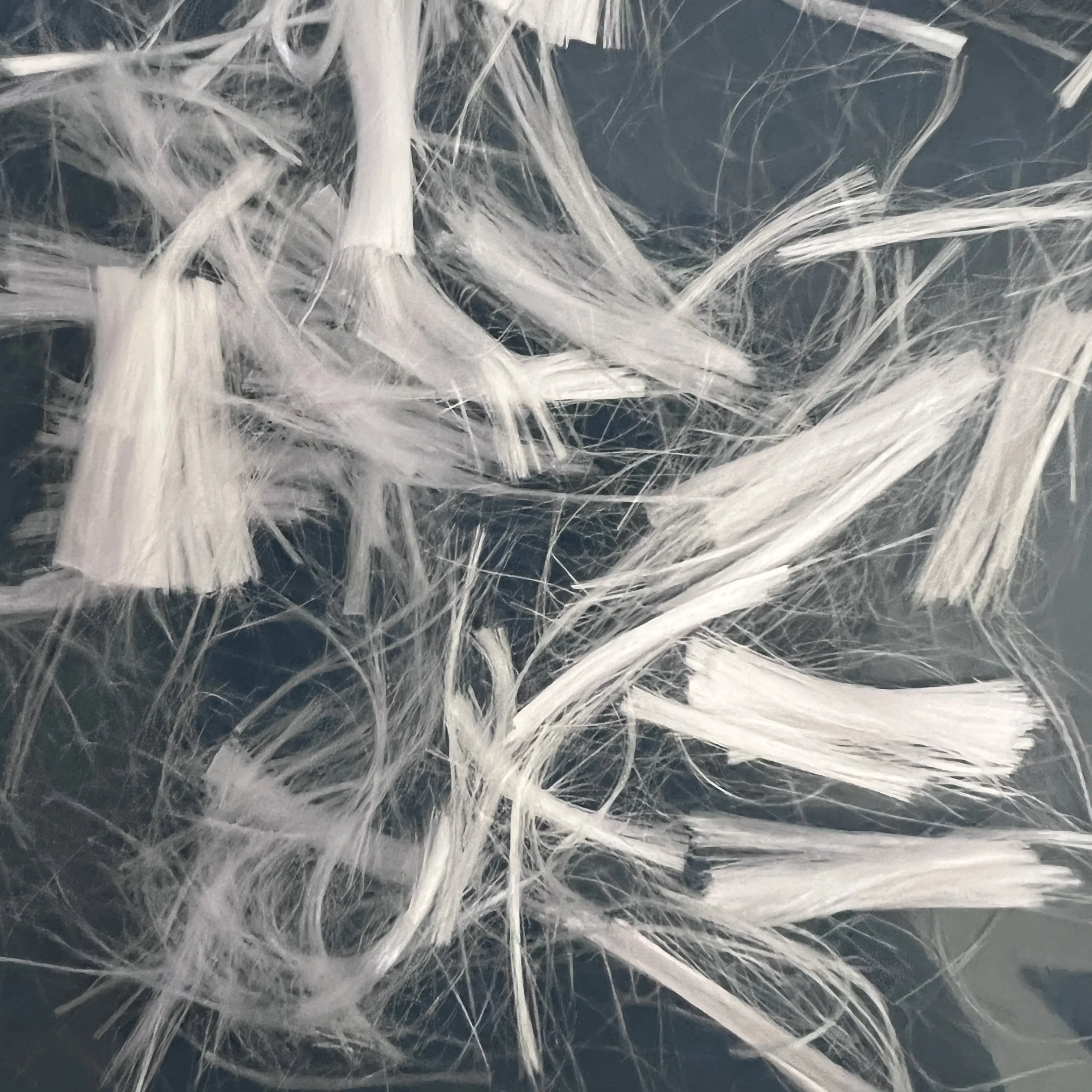

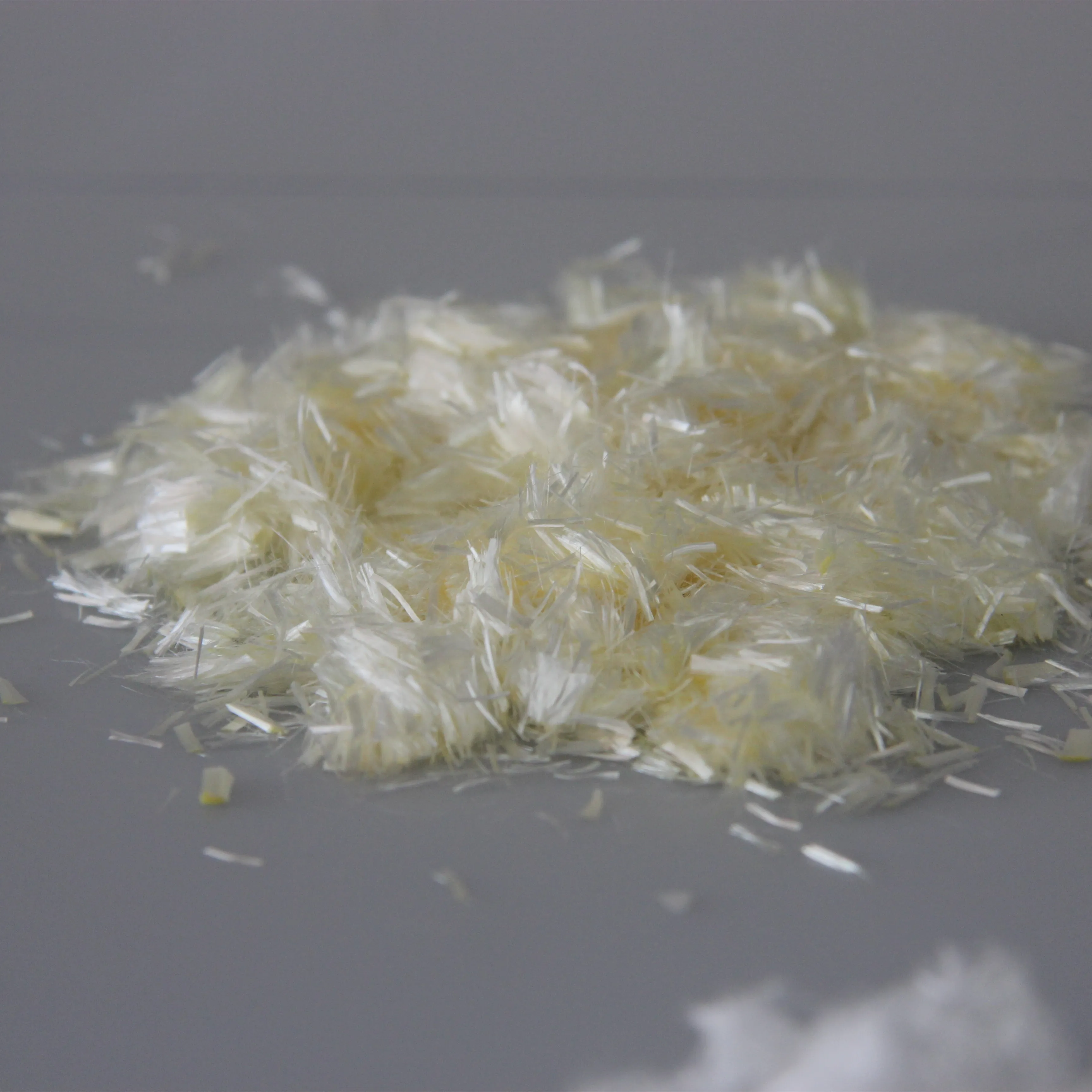

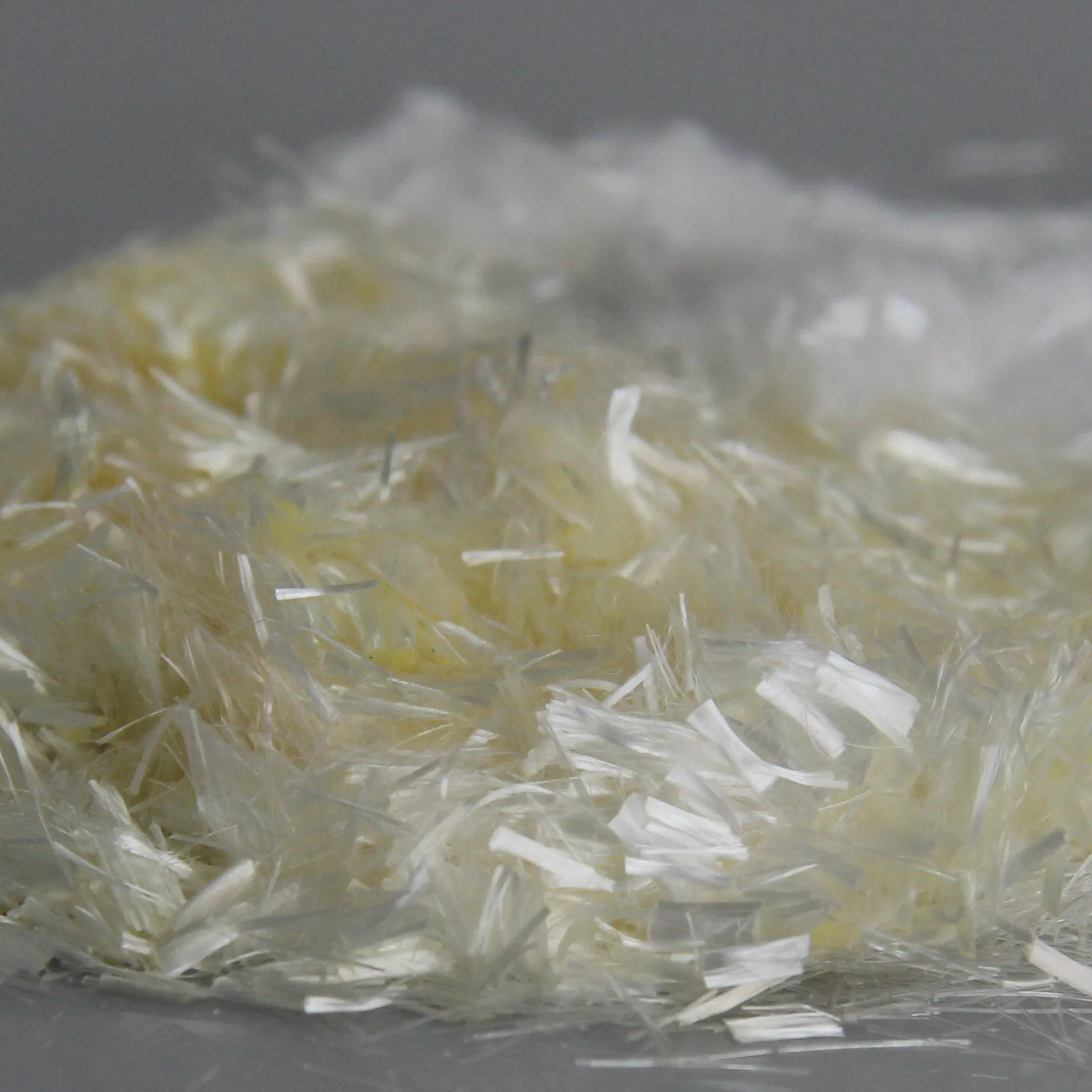

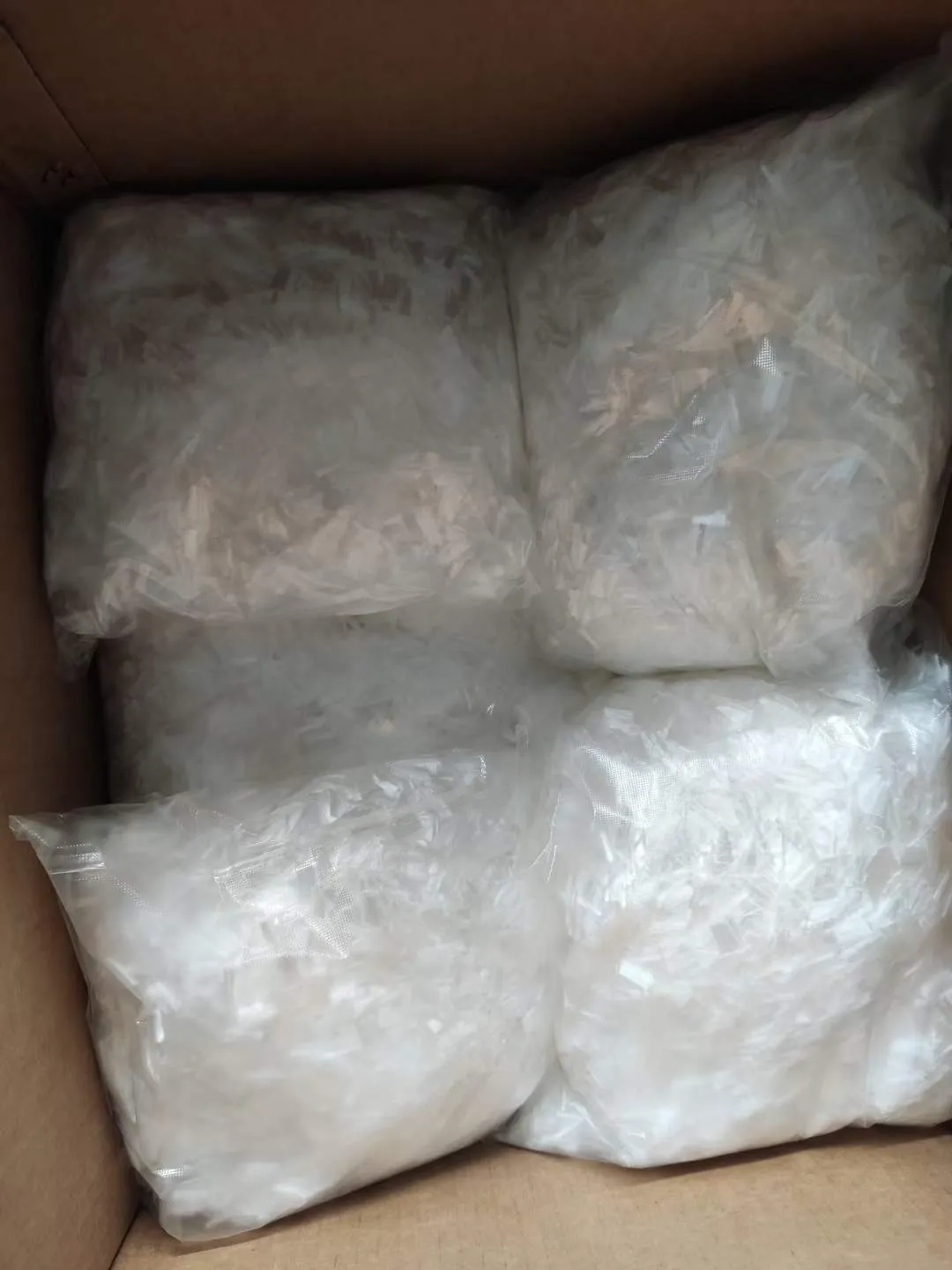

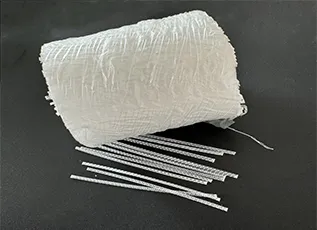

Micro Synthetic Fiber

The micro synthetic fiber is a high-performance micro-reinforcement system for concrete, made from 100% virgin polypropylene monofilament fibers with no reprocessed olefin materials. This micro synthetic fiber is specifically designed to control plastic shrinkage and settlement cracking in concrete. Micro synthetic fiber stands out for its durability and compatibility, providing reliable reinforcement that adapts seamlessly to various concrete formulations.