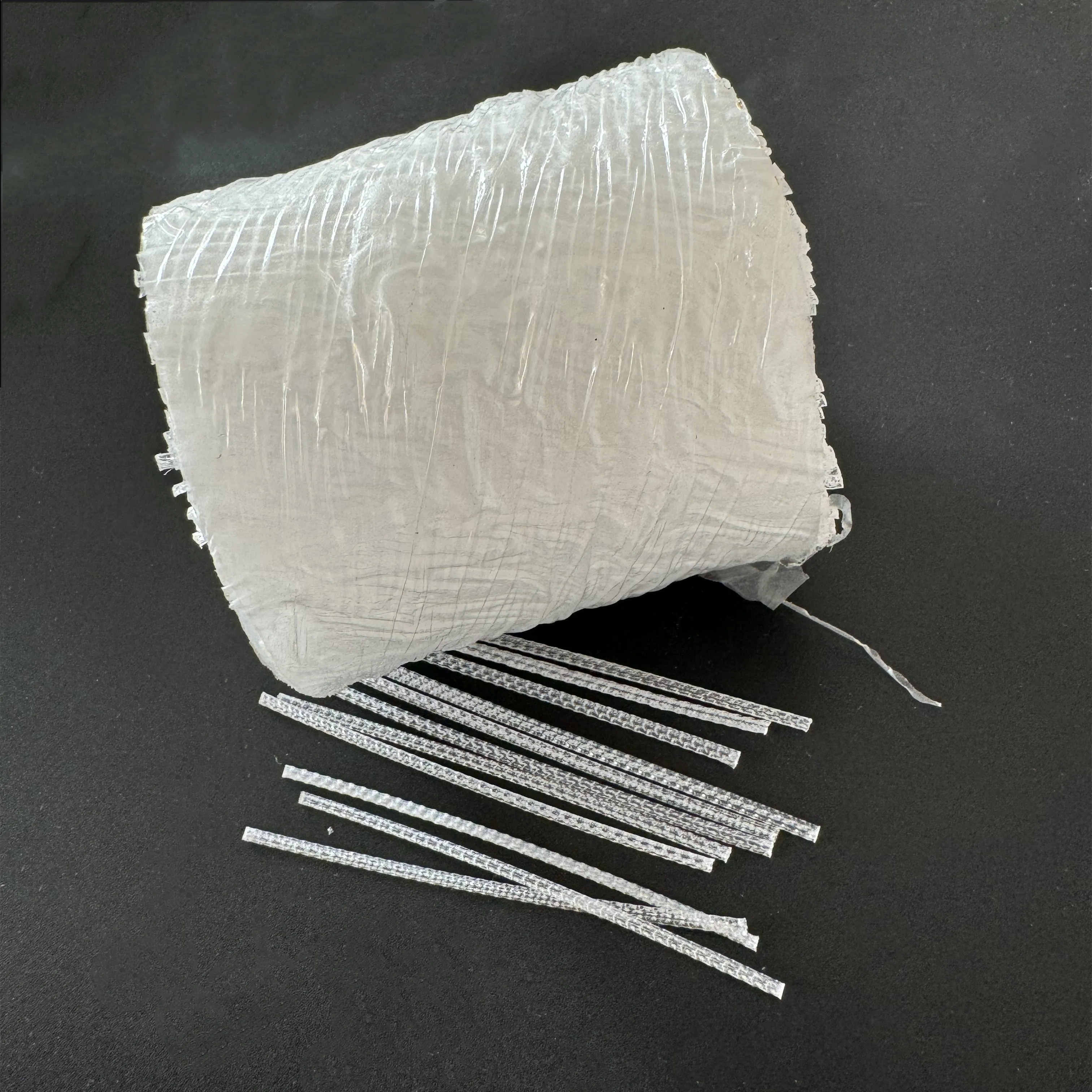

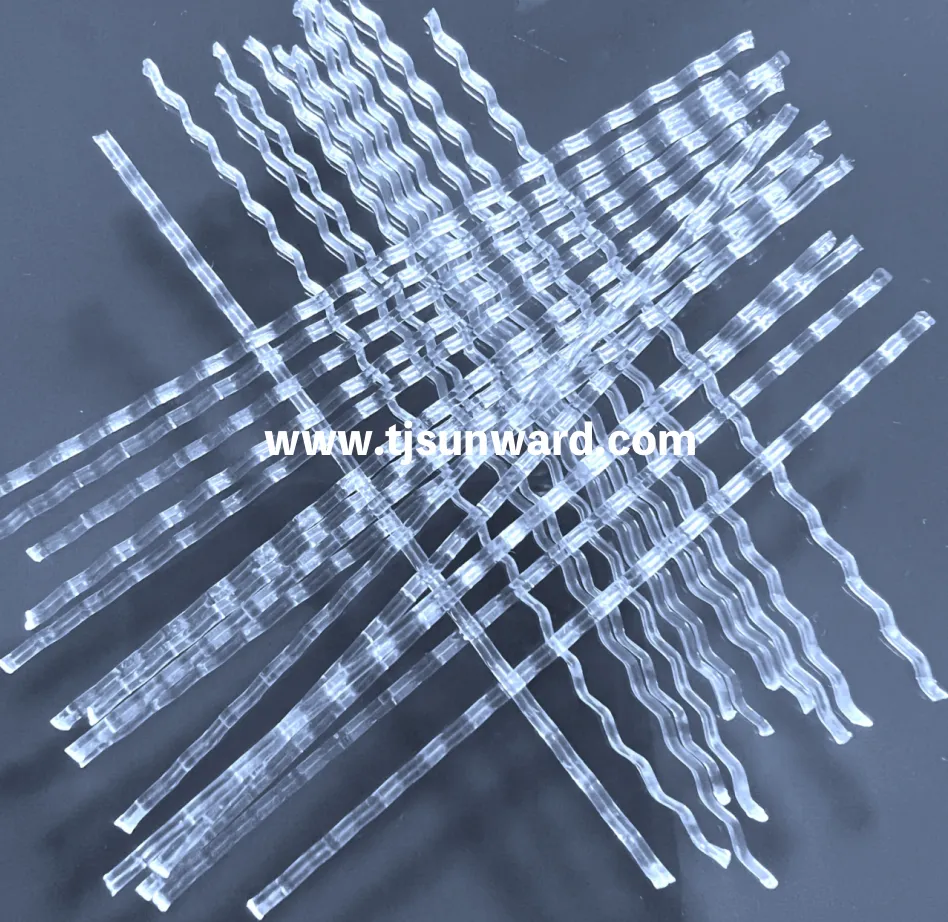

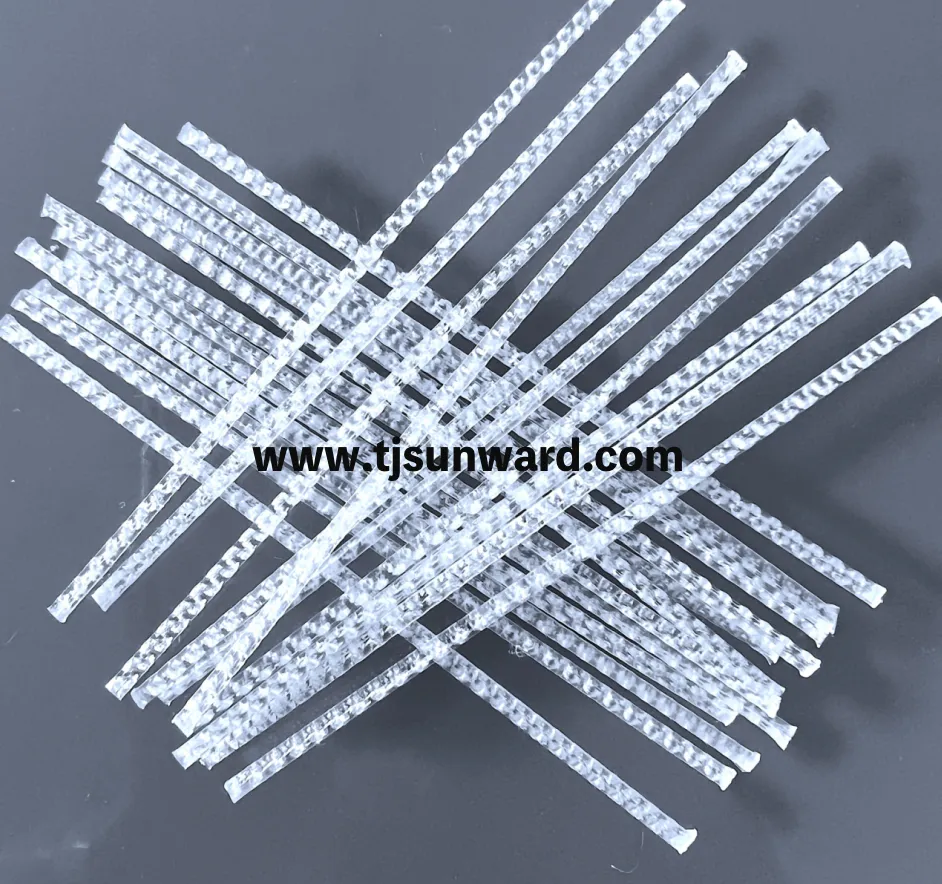

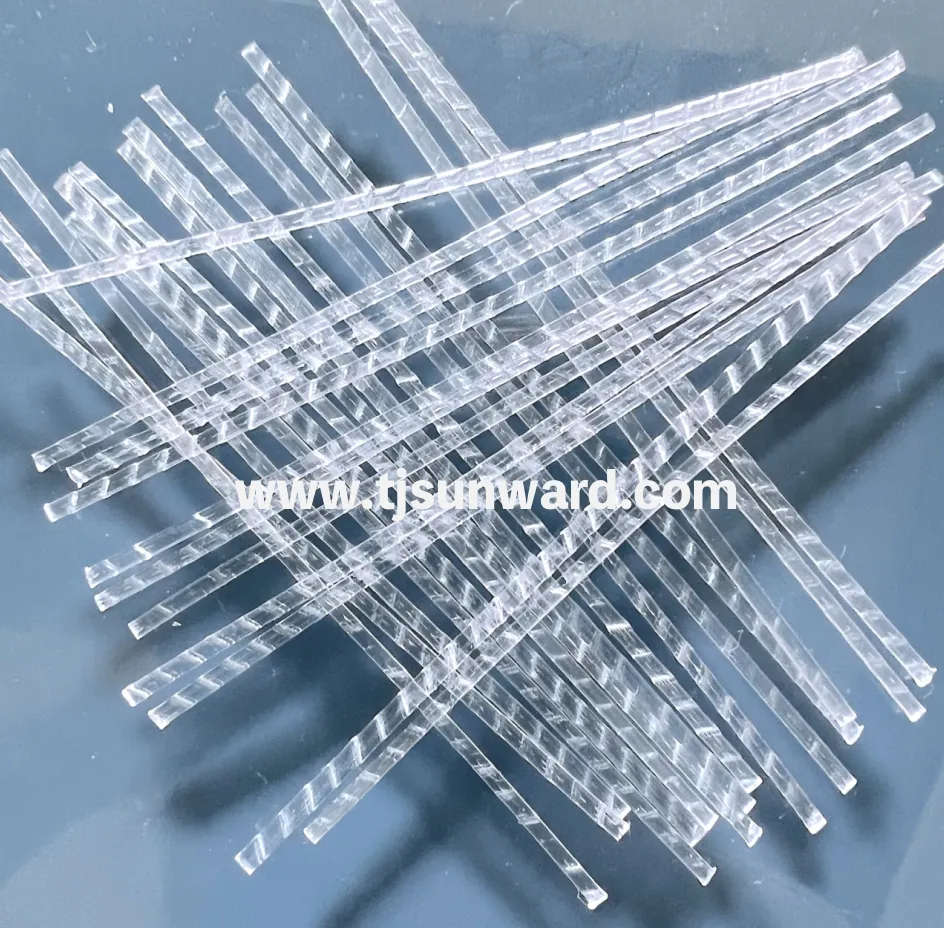

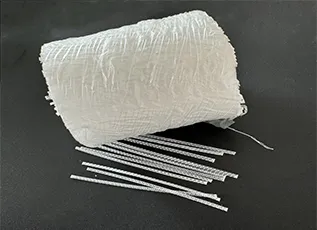

Macro Synthetic Fiber

Competitive Macro Synthetic Fiber Prices: Stronger Concrete, Lower Costs

Macro synthetic fiber is a high‑performance polypropylene reinforcement used as an alternative to steel fibers and welded wire mesh in precast concrete and shotcrete. Macro synthetic fiber in concrete enhances durability, toughness, and crack resistance while reducing overall project costs and complexity. With a competitive macro synthetic fiber price, it has become widely used in precast concrete, underground structures, and shotcrete reinforcement.